Brand: Feeney®

Feeney® CableRail Kits End Cap, Black (10 Each)

-10%

$6.98

$7.75

Feeney® CableRail Kits End Cap, Black (10 Each) Feeney® CableRail Kits for a Wood Frame, Feeney®...

Brand: Feeney®

Feeney® CableRail Kits End Cap, White (10 Each)

-10%

$6.98

$7.75

Feeney® CableRail Kits End Cap, White (10 Each) Feeney® CableRail Kits for a Wood Frame, Feeney®...

Brand: Feeney®

Feeney® CableRail Kits End Cap, Brown (10 Each)

-10%

$6.98

$7.75

Feeney® CableRail Kits End Cap, Brown (10 Each) Feeney® CableRail Kits for a Wood Frame, Feeney®...

Brand: Feeney®

Feeney® CableRail Kits End Cap, Silver (10 Each)

-10%

$6.98

$7.75

Feeney® CableRail Kits End Cap, Silver (10 Each) Feeney® CableRail Kits for a Wood Frame, Feeney®...

Brand: Feeney®

Feeney® CableRail Kits End Cap, Bronze (10 Each)

-10%

$6.98

$7.75

Feeney® CableRail Kits End Cap, Bronze (10 Each) Feeney® CableRail Kits for a Wood Frame, Feeney®...

Brand: Feeney®

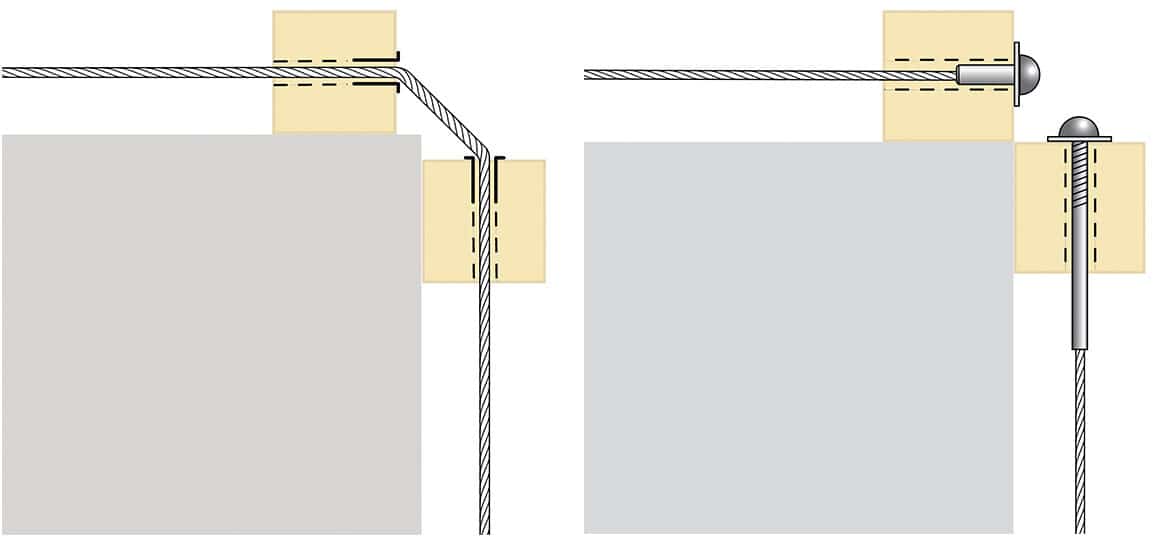

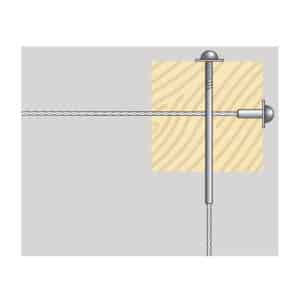

Feeney® CableRail (1/8") Quick-Connect® Lag (Each)

-10%

$22.77

$25.30

Feeney® CableRail (1/8") Quick-Connect® Lag (Each)Feeney® CableRail Fittings+Bulk Cable for a Wood Frame, Feeney® CableRail...

Brand: Feeney®

Feeney® CableRail Kits End Cap, Stainless Steel Crown (4 Each)

-10%

$26.10

$29.00

Feeney® CableRail Kits End Cap, Stainless Steel Crown (4 Each)Feeney® CableRail Kits for a Wood...

Brand: Feeney®

Feeney® CableRail Kits End Cap, Stainless Steel Chamfer (4 Each)

-10%

$26.10

$29.00

Feeney® CableRail Kits End Cap, Stainless Steel Chamfer (4 Each)Feeney® CableRail Kits for a Wood...

Brand: Feeney®

Feeney® CableRail (1/8") Quick-Connect® Threaded Terminal (Each)

-10%

$26.42

$29.35

Feeney® CableRail (1/8") Quick-Connect® Threaded Terminal (Each)Feeney® CableRail Fittings+Bulk Cable for a Wood Frame, Feeney®...

Brand: Feeney®

Feeney® CableRail (1/8") Quick-Connect® Pivot (Each)

-10%

$27.23

$30.25

Feeney® CableRail (1/8") Quick-Connect® Pivot (Each)Feeney® CableRail Fittings+Bulk Cable for a Wood Frame, Feeney® CableRail...

Brand: Feeney®

Feeney® CableRail (1/8") Quick-Connect® Surface Mount (Each)

-10%

$28.35

$31.50

Feeney® CableRail (1/8") Quick-Connect® Surface Mount (Each)Feeney® CableRail Fittings+Bulk Cable for a Wood Frame, Feeney®...

Brand: Feeney®

Feeney® CableRail (1/8") Quick-Connect® Beveled Washer (4 Each)

-10%

$29.52

$32.80

Feeney® CableRail (1/8") Quick-Connect® Beveled Washer (4 Each)Feeney® CableRail Kits for a Wood Frame, Feeney®...